A New Sweetener Coming Soon : Nectar !

Since 2016, our research and development team has been working on an innovative new project that will allow CDL to reach new markets and make even greater use of maple products.

Many food processing companies are interested in a natural maple concentrate or sweetener that has a stable flavour, is highly nutritious and can be stored for a long time at room temperature. We began exploring this idea when consumers and companies in Europe and North America started showing real interest in natural beverages like maple and birch sap. Today, we are proud to be able to explain our approach and the many opportunities offered by this new process.

SAP AND MICROORGANISMS

As you probably know, raw sap is nearly sterile when it is extracted from the tree. However, it can later be contaminated in the taps, in the collection system or during storage. Currently, sap and concentrate have a very short shelf life, but refrigerated storage and transportation remain expensive and impractical on a commercial scale. The sap composition makes it a good host for microorganisms, so we needed to develop a stabilization process that would allow the sap to be stored at room temperature for long periods while keeping it as close to raw as possible. And above all, we needed to do it without chemicals, since the sap is largely desirable because it’s natural.

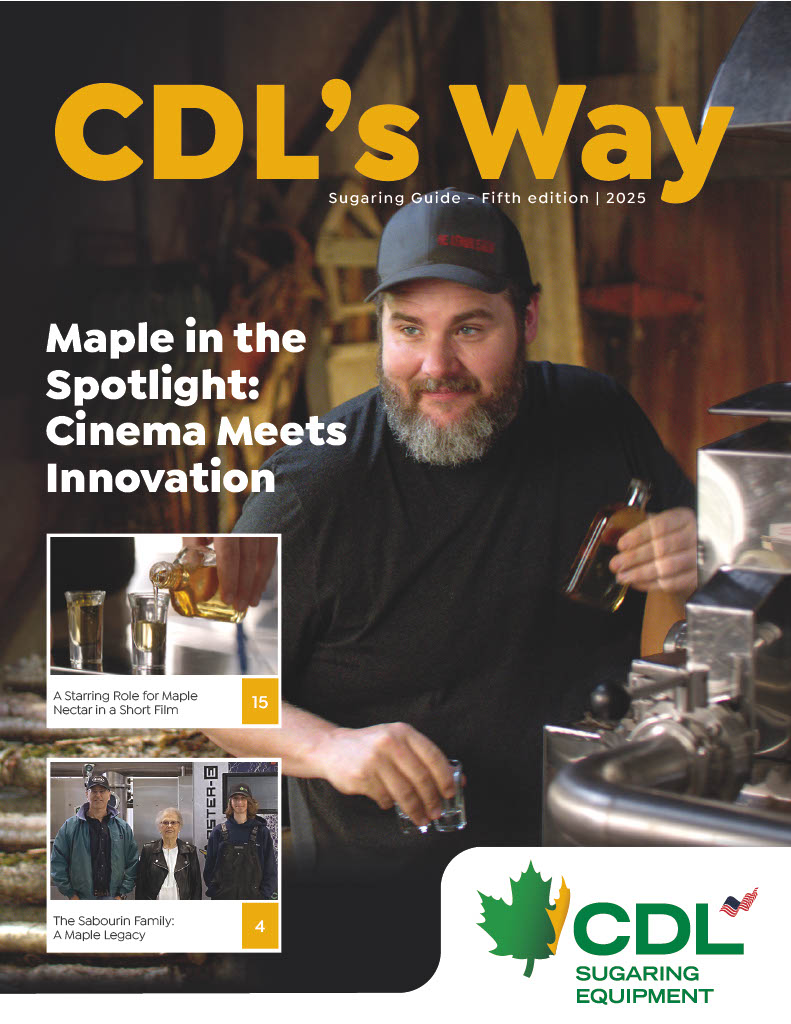

From maple sap to maple nectar, each bottle corresponds to one steps of the process

A BRIEF LOOK AT THE PROCESS

Our process consists of preserving the sap as a concentrate or rather a concentrated product called nectar. That nectar has a final Brix of over 60. It is not altered, denatured or overheated, which gives it the best nutritional value possible. Instead, it is concentrated through mechanical filtration and gentle heating. Note that while the sap is heated, it is never cooked or boiled above 100 °C (212 °F).

First, the sap is sent through an ultrafiltration unit, which stabilizes it by eliminating any yeast and microorganisms that could alter it as it is being concentrated. Then it goes through a reverse osmosis process to increase the Brix and simplify the next step, which involves evaporating the water (without cooking the sap) to keep the natural sap’s original properties. At this point, the sap has reached 60 to 70 degrees Brix, depending on the needs. It has become a stable product—maple nectar—that can be stored at room temperature.

The process can be fully automated, which means a quick return on investment with very low energy demand. It is also simple enough that any large or mid-sized maple syrup producer can use it. Finally, it lowers production costs and creates an interesting maple swettener.

Maple nectar seen more closely

This new, unique, 100% natural sweetener is ideal for the food processing industry, since maple nectar retains all the nutrients and properties of maple sap.

THE SWEETENER OF CHOICE FOR FOOD PROCESSING

This new, unique, 100% natural sweetener is ideal for the food processing industry, since maple nectar retains all the nutrients and properties of maple sap. What’s more: it has almost unlimited potential in food processing. Nectar can easily replace the liquid sugars used by many large food and food processing companies.

It can be kept in a warehouse, making it easier to use, store, and commercialize for food processing companies.

STAY TUNED!

We will soon be making some maple nectar units available exclusively to our customers. A technology showcase project is also underway to allow maple syrup producers who are interested in the process to visit and learn more about this promising CDL innovation for the maple syrup industry