Automating your sugar bush, from forest to barrels

As in so many other fields, smart systems are part of the trends and solutions to many issues in maple syrup production because they help us make better decisions.

When maple sap is flowing almost continuously during the short sugaring season, every minute counts in harvesting every last drop.

For some, the four to six weeks of sugaring account for their entire annual income. A lower yield due to equipment leaks, failure, or malfunction can have a serious impact on business operations or the operator’s livelihood. That’s why it’s critical to have a smart system that lets you keep track of every detail.

Not only does this intelligent technology give you 24-hour access to vital data for your sugar bush, it also gives you the latitude to automate certain actions and processes.

CDL’s 4.0 vision is to create a 100% automated, remote-controllable sugar bush, establish an encompassing synergy, and interconnect all the automated steps of maple syrup production, from the sap that drips in the forest to the syrup that drips into the barrel.

CDL has been working towards this 4.0 vision for several years now. Step by step, Industry 4.0 in the field of maple syrup production has followed the journey of maple sap from forest to

pumping station, by way of tanks to the reverse osmosis system (RO) and, now, to the evaporation stage with the introduction of the Master-E.

Thanks to the CDL Intelligence system, you can now use automation to manage your sugar bush.

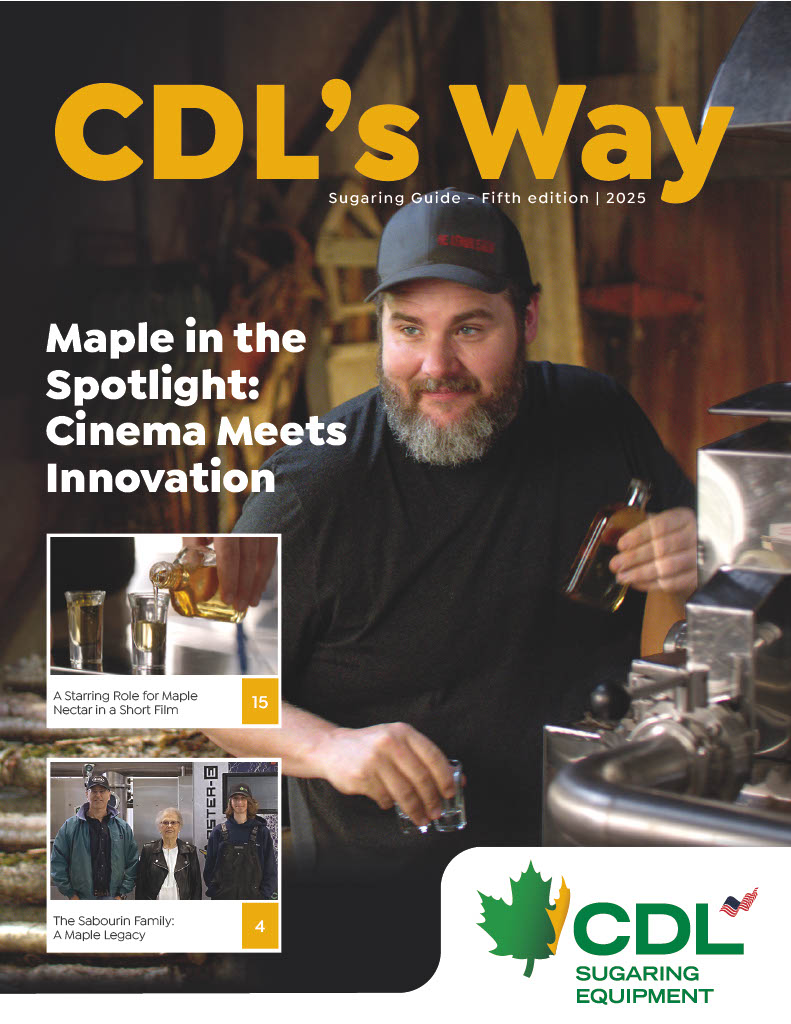

Photo taken at the Érablière de la Coulée Creuse of Mr. Sylvain Patry

What, exactly, can CDL Intelligence do for you?

First of all, the premise is that you can access your data in real time, all the time, from anywhere. Not only does the CDL Intelligence system gather the key data from your sugar bush via a single comprehensive and ergonomic platform, it gives you remote control over vacuum pumps, transfer pumps, various valves, the RO, and the electric evaporator. With this information in hand, you can determine whether your equipment is working properly and even control it.

Some processes are still hard to automate. One example is repairing leaks in the forest. Even here, CDL Intelligence is your ally. The system will give you the information you need to take immediate action at specific locations using a colour-coded virtual map of your sugar bush. Can you imagine the savings in labour and yield?

Automating a sugar bush is a process that takes time. As the saying goes, the only way to eat an elephant is one bite at a time. CDL decided to tackle the sugar bush section by section. In

recent years, technology has arrived in forests with vacuum sensors, in pumping stations with remote pump control and vacuum modulation, in tanks with level monitoring, in ROs with remote control and automation, and— most recently—in evaporation with the Master-E, which can produce up to 2.5 barrels of syrup per hour at the touch of a button.

What’s next for you at CDL?

CDL has accomplished a lot, but there is still work ahead of us. The next steps in achieving Maple Syrup Production 4.0 are syrup filtration and barrelling. Both stages are rife with challenges. Filtration is a complex step that requires a lot of work and a combination of factors for the syrup to pass through the press: filters, powder, syrup temperature, vacuum, etc. Anyone who has tried their hand at pressing syrup knows this step is a challenge, even for humans. How can an automated system manage and interconnect all these factors? These are

the questions our R&D team is asking.

The same is true of barrelling. Bulky and heavy, syrup barrels require strength to handle. What’s the best way to move them? A conveyor belt? A carousel? And what about filling them? With a sensor and robotic arm, an integrated flowmeter?

For now, these are some of the issues the CDL team will be working on in the coming months and, perhaps, years. These next steps will take Maple Syrup Production 4.0 full circle.